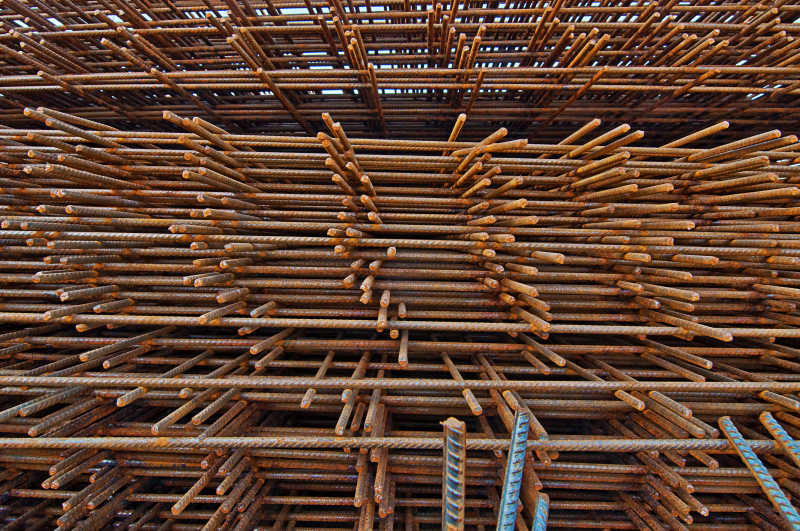

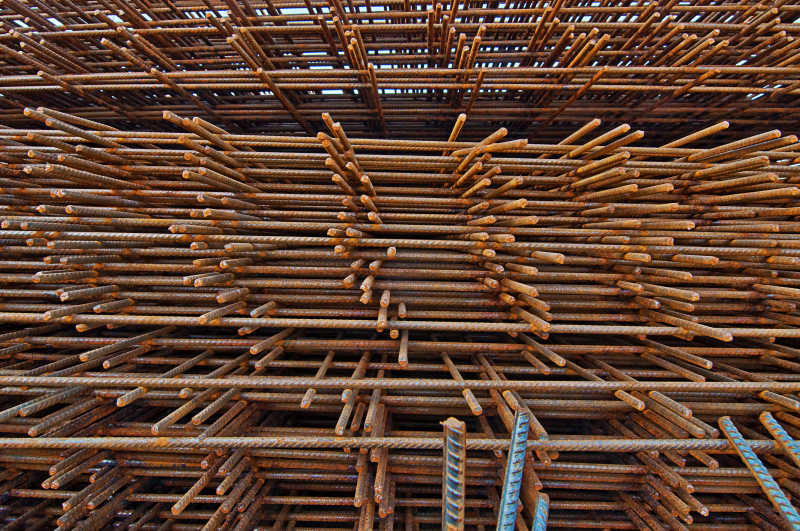

钢筋加工制作时,要将钢筋加工表与设计图复核,检查下料表是否有错误和遗漏,对每种钢筋要按下料表检查是否达到要求,经过这两道检查后,再按下料表放出实样,试制合格后方可成批制作,加工好的钢筋要挂牌堆放整齐有序。

When making reinforcing bars, we should check the processing tables and design drawings, check whether there are errors and omissions in the cutting tables, and check whether each reinforcing bar meets the requirements according to the cutting tables. After these two checks, we can put out the actual samples according to the cutting tables. After trial production, we can make the reinforcing bars in batches. The processed reinforcing bars should be listed and stacked orderly.

施工中如需要钢筋代换时,必须充分了解设计意图和代换材料性能,严格遵守现行钢筋砼设计规范的各种规定,并不得以等面积的高强度钢筋代换低强度的钢筋。凡重要部位的钢筋代换,须征得甲方、设计单位同意,并有书面通知时方可代换。

If steel bar replacement is needed in construction, it is necessary to fully understand the design intent and performance of replacement materials, strictly abide by various provisions of the current design code for reinforced concrete, and not to replace low strength steel bar with high strength steel bar of equal area. Replacement of reinforcing bars in important parts shall be subject to the consent of Party A and the design unit, and may only be done with written notification.

(1)钢筋表面应洁净,粘着的油污、泥土、浮锈使用前必须清理干净,可结合冷拉工艺除锈。

(1) The surface of reinforcing bar should be clean, and the oil, clay and floating rust must be cleaned up before using, and the rust can be removed by cold drawing process.

(2)钢筋调直,可用机械或人工调直。经调直后的钢筋不得有局部弯曲、死弯、小波浪形,其表面伤痕不应使钢筋截面减小5%。

(2) The steel bar can be straightened by mechanical or manual means. After straightening, the steel bar must not have local bending, dead bending or wavelet wave shape, and its surface scars should not reduce the section of the steel bar by 5%.

(3)钢筋切断应根据钢筋号、直径、长度和数量,长短搭配,先断长料后断短料,尽量减少和缩短钢筋短头,以节约钢材。

(3) The steel bar should be cut according to the size, diameter, length and quantity of the steel bar, the length should be matched, the long material should be broken first and then the short material should be broken, so as to minimize and shorten the short end of the steel bar, so as to save steel.

(4)钢筋弯钩或弯曲:

(4) Bending or bending of reinforcing bars:

①钢筋弯钩。形式有三种,分别为半圆弯钩、直弯钩及斜弯钩。钢筋弯曲后,弯曲处内皮收缩、外皮延伸、轴线长度不变,弯曲处形成圆弧,弯起后尺寸不大于下料尺寸,应考虑弯曲调整值。

Reinforcement hook. There are three types of hooks: semi-circular hook, straight hook and oblique hook. After bending, the endothelium shrinks, the outer skin extends, the axis length remains unchanged, and the bending part forms an arc. The dimension after bending is not larger than the blanking size, so the bending adjustment value should be considered.

钢筋弯心直径为2.5d,平直部分为3d。钢筋弯钩增加长度的理论计算值:对转半圆弯钩为6.25d,对直弯钩为3.5d,对斜弯钩为4.9d。

The diameter of bending center of steel bar is 2.5 days and the straight part is 3 days. The theoretical calculation value of increasing the length of steel bar hook is 6.25 days for counter-rotating semi-circular hook, 3.5 days for straight hook and 4.9 days for oblique hook.

②弯起钢筋。中间部位弯折处的弯曲直径D,不小于钢筋直径的5倍。

(2) Bend the reinforcing bar. The bending diameter D at the bending point of the middle part is not less than 5 times of the diameter of the reinforcing bar.

③箍筋。箍筋的末端应作弯钩,弯钩形式应符合设计要求。箍筋调整,即为弯钩增加长度和弯曲调整值两项之差或和,根据箍筋量外包尺寸或内包尺寸而定。

3. Stirrup. The end of stirrups should be bent hooks, and the form of bent hooks should meet the design requirements. The stirrup adjustment is the difference or sum of the length of the bending hook and the bending adjustment value, depending on the size of the stirrup outsourcing or the size of the inner package.

④钢筋下料长度应根据构件尺寸、混凝土保护层厚度,钢筋弯曲调整值和弯钩增加长度等规定综合考虑。

(4) The length of steel bars should be considered comprehensively according to the size of members, the thickness of concrete cover, the bending adjustment value of steel bars and the length of bending hooks.

a. 直钢筋下料长度=构件长度―保护层厚度+弯钩增加长度

A. Cutting length of straight reinforcement = length of member - thickness of protective layer + length of bending hook

b. 弯起钢筋下料长度=直段长度+斜弯长度-弯曲调整值+弯钩增加长度

B. Cutting length of bending bar = straight length + oblique length - bending adjustment value + hook length increase

c. 箍筋下料长度=箍筋内周长+箍筋调整值+弯钩增加长度

C. Cutting length of stirrups = inner circumference of stirrups + adjustment value of stirrups + increase length of bending hooks

钢筋绑扎与安装

Binding and Installation of Reinforcement Bars

钢筋绑扎前先认真熟悉图纸,检查配料表与图纸、设计是否有出入,仔细检查成品尺寸、心头是否与下料表相符。核对无误后方可进行绑扎。

Before binding steel bar, be familiar with the drawings carefully, check whether the batching table is different from the drawings and designs, and carefully check whether the finished product size and mind are in accordance with the blanking table. After checking correctly, binding can be carried out.

采用20#铁丝绑扎直径12以上钢筋,22#铁丝绑扎直径10以下钢筋。

20 # wire is used to bind bars above 12 in diameter and 22 # wire is used to bind bars below 10 in diameter.

The above contents are arranged and published by Jinan Reinforcement Wholesale Factory. For more information, please click on our official website for consultation: http://www.jzqgc.com./

咨询热线: 13605413762

咨询热线: 13605413762