一、电渣压力焊接头质量不符合要求

1. The quality of electroslag pressure welded joints does not meet the requirements

(一)现象

(1) Phenomenon

接头处轴线弯折或轴线偏疼过大,焊包不匀,并有咬边、夹渣、未熔合等现象;钢筋夹持处烧伤。

The bending or migration of the axes at the joints is too large, the welding package is uneven, and there are some phenomena such as undercut, slag inclusion, non-fusion, etc. The reinforcing bar is burned at the clamping position.

(二)原因剖析

(2) Cause analysis

1、钢筋端部歪扭不直,整理不干净或端面不平;钢筋装置不正,轴线偏移,机具损坏,造成钢筋晃动和位移;焊接完成后,接头未经充分冷却;

1. The end of the reinforcing bar is not straight, clean or uneven; the installation of the reinforcing bar is not correct, the axis is offset, and the machine tool is damaged, resulting in the sway and displacement of the reinforcing bar; after welding, the joint has not been fully cooled;

2、焊接工艺方法使用不妥,焊接参数挑选不合适,操作技术不过关;

2. Improper use of welding technology, inappropriate selection of welding parameters and poor operation technology;

3、焊剂装填不匀,或受潮。

3. Flux filling is uneven or damp.

(三)防治办法

(3) Measures for prevention and control

1、焊接前应矫正或切除钢筋端部过于弯折或歪曲的部分,并予以铲除干净,钢筋端面应磨平;

1. Before welding, the bending or distorted part of the end of the reinforcing bar should be corrected or removed, and the end of the reinforcing bar should be eradicated, and the end face of the reinforcing bar should be ground flat.

2、钢筋加工装置应由持证焊工进行,装置钢筋时要注意钢筋或夹具轴线是否在同一直线上,钢筋是否装置结实,过长的钢筋装置时应有置于同一水平面的延伸架,如机具损坏,特别是焊接夹具垫块损坏应及时修理或替换,经检验合格后方准焊接;

2. Reinforcement processing equipment should be carried out by licensed welders. When installing reinforcing bars, attention should be paid to whether the axes of reinforcing bars or fixtures are on the same straight line, whether the reinforcing bars are strong or not, and if the reinforcing bars are too long, an extension frame should be placed on the same horizontal plane. If the machine tool is damaged, especially the damage of welding fixture pads should be repaired or replaced in time, and quasi-welded

3、依据《钢筋焊接及检验规程》(JCJ18)合理挑选焊接参数,正确掌握操作方法。焊接完成后,应视状况坚持冷却1~2min后,待接头有足够的强度时再拆除机具或移动;

3. Reasonable selection of welding parameters and correct grasp of operation methods according to the Code for Welding and Inspection of Reinforcement Bars (JCJ18). After the welding is completed, the machine tool should be removed or moved after cooling for 1 to 2 minutes according to the condition, and when the joint has enough strength.

4、焊工有必要持有上岗证。钢筋焊接前,有必要依据施工条件进行试焊,合格后方可施焊;

4. It is necessary for welders to hold a job certificate. Before welding, it is necessary to carry out trial welding according to construction conditions, and only after qualified can it be welded.

5、焊接完成后有必要坚持自检。对接头弯折和偏疼超过标准的及未焊透的接头,应切除热影响区后从头焊接或采取补强焊接办法;对脆性断裂的接头应按规定进行复验,不合格的接头应切除热影响区后从头焊接。

5. It is necessary to insist on self-inspection after welding. For joints with bending and migration exceeding the standard and incomplete penetration, the heat affected zone should be removed and then ab initio welding or reinforcing welding should be adopted; for joints with brittle fracture, the required re-inspection should be carried out, and for unqualified joints, the heat affected zone should be removed and ab initio welding should be adopted.

二、直螺纹丝扣加工缺陷

2. Machining Defects of Straight Thread Screw Bucks

(一)现象:

(1) Phenomena:

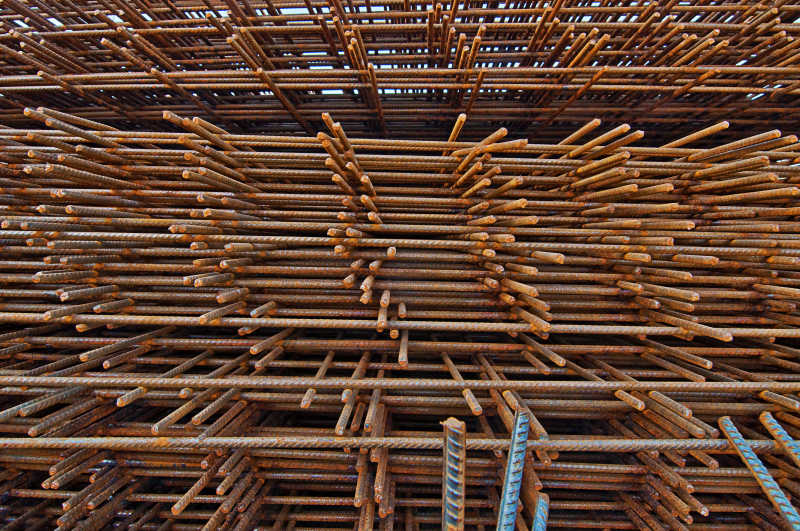

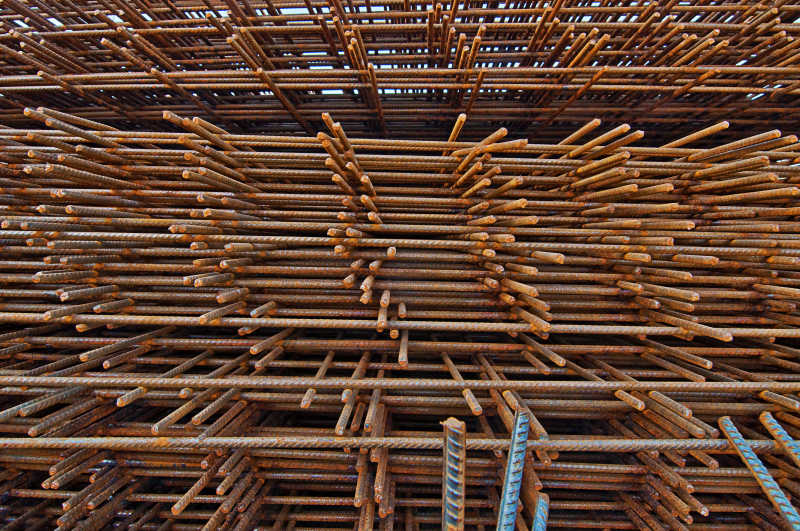

丝扣残缺、数量不行、丝头端部不平整等(如图1、图2)。

Wire buckles are incomplete, the number is not good, and the end of the wire head is uneven (Fig. 1 and Fig. 2).

(二)原因剖析:

(2) Cause analysis:

1、操作工人未经培训,现场交底不清;

1. Operators have not been trained, and the on-site information is unclear.

2、进程质量操控不严厉,加工机械维护不到位;

2. The process quality control is not strict and the maintenance of processing machinery is not in place.

3、丝头加工后未及时加戴维护帽进行维护;

3. The silk head was not maintained in time with David's cap after processing.

4、钢筋端部直接选用切断机切开。

4. The end of reinforcing bar is cut by cutting machine directly.

(三)防治办法:

(3) Measures for prevention and control:

1、钢筋接头丝扣加工的操作人员有必要经过培训、考核、持证上岗;

1. It is necessary for the operator of steel bar joint thread processing to be trained, assessed and certified.

2、现场须配备通规、止规等检测工具,对加工的丝头要经常性检查;

2. Inspection tools such as general rules and stop rules should be equipped on the spot, and regular inspection should be carried out on the processed silk heads.

3、合格的丝头应及时加装维护帽;

3. Qualified silk heads should be equipped with maintenance caps in time.

4、钢筋端头应选用无齿锯切开,以确保钢筋端部平整。

4. The end of reinforcing bar should be cut with toothless saw to ensure that the end of reinforcing bar is flat.

咨询热线: 13605413762

咨询热线: 13605413762